The Aircraft Performance Company GmbH

The Aircraft Performance Company GmbH

We start

with a cleaner sky.

With expertise and ingenuity we make a significant impact on

the future of today’s and tomorrow’s aviation regarding lower emissions and environmental pollution.

In 2016, the Aircraft Performance Company GmbH has been founded by the two aviation engineers and aeronautics enthusiasts Hans-Jörg Petscher and Raymond Lucas.

The built up of an interdisciplinary core team starts in Hamburg, Germany.

Our focus is set on design and performance improvements resulting in increased fuel efficiencies of legacy and next generation aircraft.

We offer turnkey programs that emanate from creativity and curiosity and transform hands-on solutions into a tangible reality.

Our first product is a retrofit-able multifinger-wingtip which we named TRINITAIR.

This technology provides an enhanced aerodynamic solution supporting aircraft-manufacturers and airlines in their commitment to reduce CO2 emissions.

We make aircraft novel

Plug & Fly

By means of our Wingtip Retrofit Solution,

developed for airliners, this is our first step forward to reduce aviation-related greenhouse gas emissions.

Our mission

Cost-effective, creative and hands-on solutions for valuable

in-service aircraft.

For a cleaner sky.

For a greener planet.

Our new wingtip technology TRINITAIR is the first step towards our goal to make a notable contribution to reduce the aviation related greenhouse gas emissions in the currently existing fleets.

Winglets are a truly great invention. They increase the effective aspect ratio of a wing without adding greatly to the structural stress and the weight of its structure.

Winglets are key to achieve a fuel burn reduction with most wing designs. Our three finger wingtip TRINITAIR configuration enhances the efficiency of this proven technology.

TRINITAIR was further designed as a cost-effective retrofit solution for valuable in-service aircraft.

Our Plug & Fly concept increases the number of aircraft which will be retrofitted and by this the number of aircraft which generate less emissions.

TRINITAIR will have the maiden flight for this new green technology on an AIRBUS A330 in 2021.

The benefits of Trinitair

PLUG

& FLY

Retrofit Wingtip

Solution

Aircraft downtime less

than one day.

LOWER

FUEL BURN

Greenhouse Gas Reduction

Lower fuel burn to reduce emissions of CO2* and NOX.

*1kg of JET A-1 aircraft fuel

generates 3.16kg of CO2

PERFORMANCE OPTIMIZATION

Performance Enhancement

Lower drag in cruise results in lower thrust setting.

Lower engine wear

Range extension

Payload increase

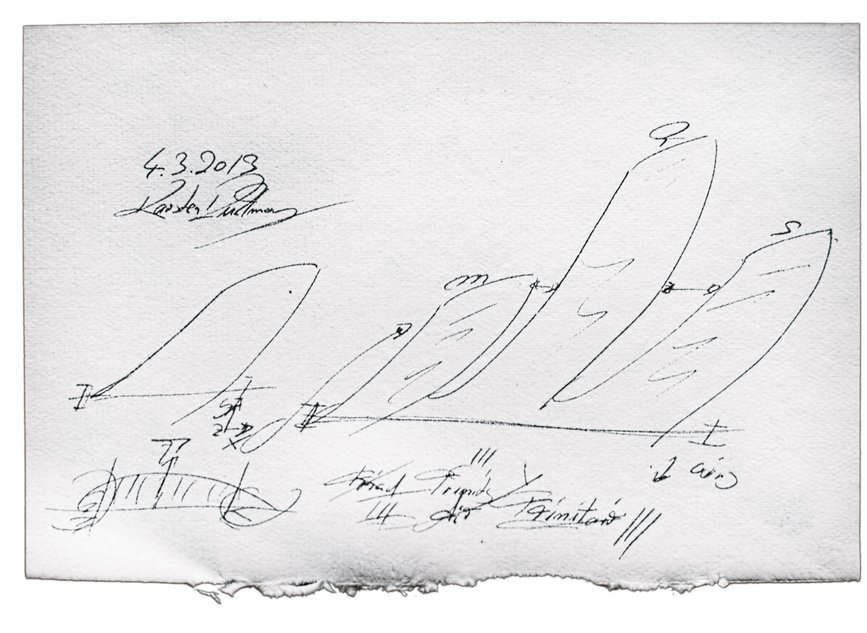

Sometimes the best ideas begin on a napkin.

Turning great ideas into sustainable solutions.

We believe: All of us can contribute to this effort.

Join and expand our path with us.